DESCRIPTION

Basic Info.

| Model NO. | SM-280T |

| Clamping Way | Hydraulic & Mechanical |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Packing List | 1 |

| Easy Broken Parts | 1 |

| Commercial Invoice | 1 |

| Certificate of Fumigation | 1 |

| Certificate of Origin | 1 |

| Transport Package | Wooden Pallet and Dust Cover |

| Trademark | K&E |

| Origin | China |

| HS Code | 8477101090 |

| Production Capacity | 500/Y |

Product Description

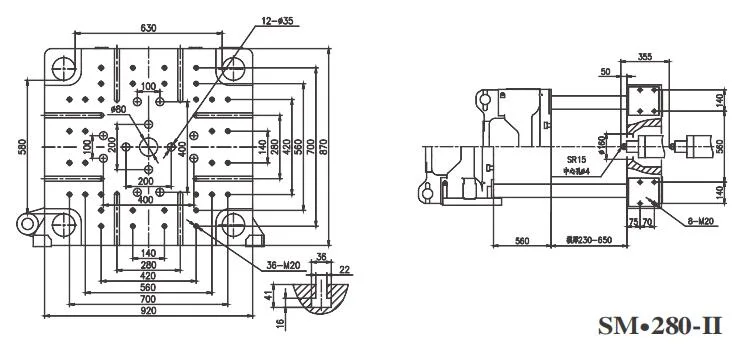

Platen Drawings:

Parameters:

| SPECIFICATION | SM-280 | |||

| SCREW TYPE | A | B | C | |

| Injection Unit | ||||

| Screw diameter | mm | 55 | 60 | 65 |

| Screw L/D ratio | L/D | 22.5 | 20.6 | 19 |

| Shot volume(theoretical) | CM3 | 665 | 792 | 929 |

| Injection weight(PS) | g | 605 | 721 | 845 |

| Injection rate | g/s | 220 | 263 | 308 |

| Injection pressure | Bar | 2190 | 1840 | 1568 |

| Screw speed | rpm | 225 | ||

| Clamping Unit | ||||

| Clamping force | KN | 2800 | ||

| Open stroke | mm | 560 | ||

| Space between tie-bars(W*H) | mm | 630*580 | ||

| Max mould height | mm | 650 | ||

| Min mould height | mm | 230 | ||

| Ejector stroke | mm | 160 | ||

| Ejector force | KN | 70 | ||

| Others | ||||

| Max pump pressure | Bar | 16 | ||

| Motor pump power | Kw | 36.7 | ||

| Heating power | Kw | 18.2 | ||

| Machine dimension(L*W*H) | M | 6.1*1.53*1.86 | ||

| Oil tank cubage | L | 400 | ||

| Machine weight | Ton | 9 | ||

Configuration List:

| Items | Brand/country | |

| Servo System | Controller | TECHMATION -8' (TAIWAN ) |

| Servo Motor | INOVANCE (CHINA) | |

| Servo Drive | INOVANCE (CHINA) | |

| Oil Pump | ECKERLE (Germany) or SUMITOMO (JAPAN ) | |

| Electric Unit | Stroke transducer | NOVO or FLTCH (Germany) |

| Breaker | Schneider (France ) or LS (Korea ) | |

| Contactor | Schneider (France ) or LS (Korea ) | |

| Air Switch | Schneider (France ) | |

| Location /Speed Sensor | Schneider (France ) | |

| Hydraulic Unit | Hydraulic Direction Valve | YUKEN (Japan) |

| Proportion back-pressure valve | North man (Taiwan) | |

| Plasticizing hydraulic Motor | DAN DUN (ITALY) | |

| Hydraulic Hose | MANULI(ITALY) or GOOD YEAR (USA) | |

| Hydraulic Sealing ring | All Italy and Japan | |

| Others Unit | Mechanical safety | Standard |

| Electric safety | Standard | |

| Mold close fast | Standard | |

| Injection Unit | Linear guide-way | |

| Air core | 1pcs | |

| Hydraulic Core | 1pcs | |

| T slots and screw holes | Standard | |

| Servo system Compared with the other manufacturers is big, Overload ability strong and stable. | ||

Related Products

-

![LC Brand Automatic UV Water Bottle Screen Printer Cylindrical Screen Printing Machine for Jars Tubes]()

LC Brand Automatic UV Water Bottle Screen Printer Cylindrical Screen Printing Machine for Jars Tubes

-

![HDPE Bottle Milk Filling Machine]()

HDPE Bottle Milk Filling Machine

-

![Highspeed Plastic Injection Molding Machine Hxh350 Produce Food Containers]()

Highspeed Plastic Injection Molding Machine Hxh350 Produce Food Containers

-

![Juice/Coffee/Flavor Water /Tea/ Dairy Drink Washing Filling Capping Machinery Juice/ Diary Processing Machine Labeling Packing Machine]()

Juice/Coffee/Flavor Water /Tea/ Dairy Drink Washing Filling Capping Machinery Juice/ Diary Processing Machine Labeling Packing Machine